Industrial computed tomography scanning for your component measurement and analysis

TPW CTinspect is your service provider for CT scanning in industrial environments. With industrial computed tomography scans as a contract measurement service, you gain non-destructive 3D insights into the internal and external geometries of your components and assemblies – from individual samples to series testing. Our services cover the entire industrial CT portfolio from component measurement to reverse engineering and provides you with data for development, quality assurance, and production. Accredited according to DIN EN ISO/IEC 17025:2018.

Practical advantages:

- Component documentation for prototypes or initial samples

- Optimization of development processes

- Reduction of development times and costs

- Control and improvement of product quality throughout the entire product life cycle

- Comparison of components before and after testing

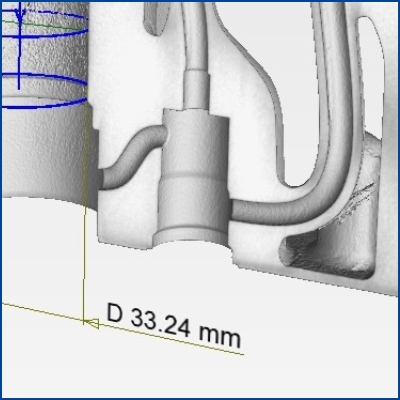

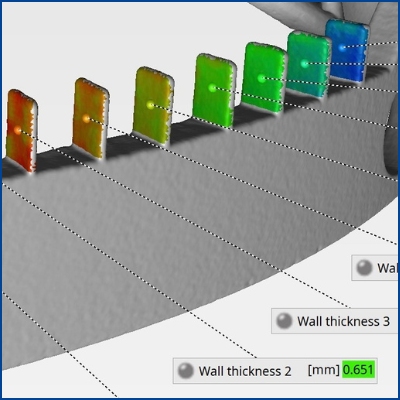

- Precise component measurement, including internal structures

- Reverse engineering of geometric data to CAD programs or production machines

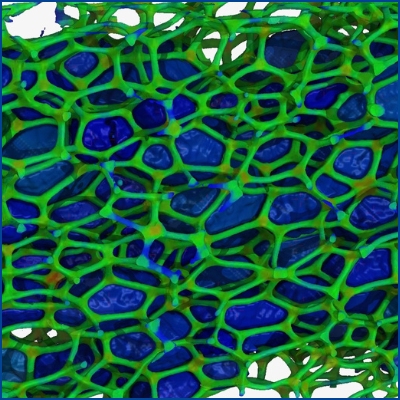

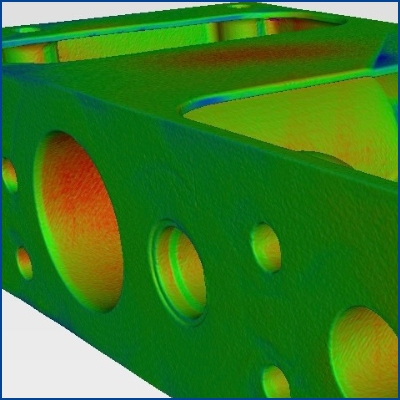

- Detection of defects at any point on the component, even in inaccessible areas

- Assembly checks, e.g., inspection of seals or fits

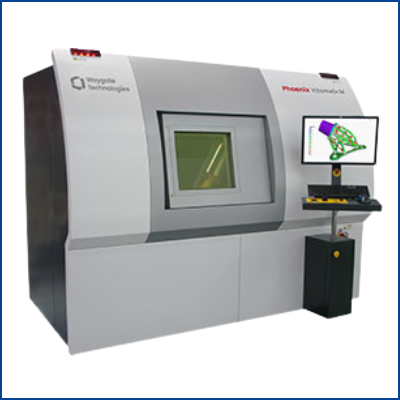

How does industrial computed tomography scanning work?

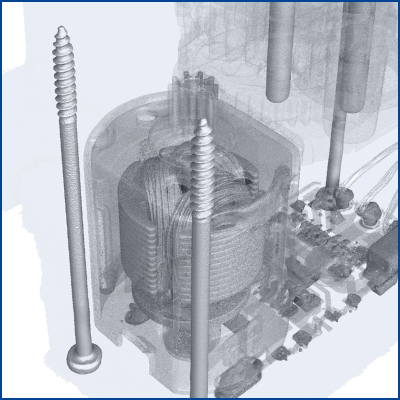

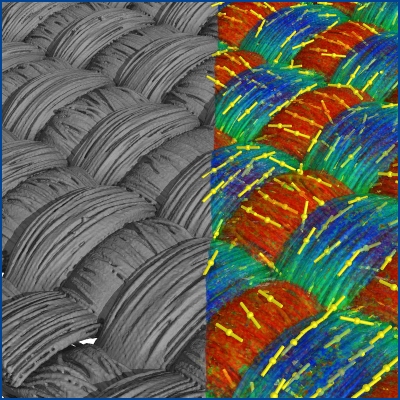

Industrial computed tomography scanning uses the same principle as medical CT scanning systems: X-rays penetrate the test object and then hit a surface detector, which records their remaining intensity. During the measurement, the object is rotated 360° in the X-ray cone, and two-dimensional digital X-ray projections are recorded in several hundred or thousand angular positions. Mathematical algorithms are then used to calculate the three-dimensional reconstruction of the measured object from these two-dimensional grayscale images.

The smallest element of the reconstruction matrix (volume element) is called a voxel (volume pixel). The edge length of a voxel is the voxel size, which is usually specified in µm. It represents a measure of detail recognition and can be approximated to the spatial resolution.

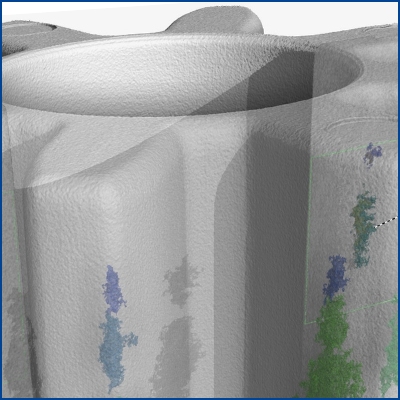

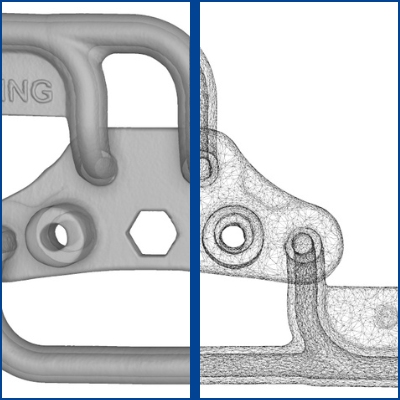

The result is a three-dimensional image of the test object in which the real external and internal geometries, including possible defects such as pores or cracks, can be visualized and analyzed.

Virtual sections can be made at any point in this 3D model. The result shows the section plane as in a destructive test – without physically destroying the component. This allows a holistic view of all component areas, and cavities and cracks, for example, can be viewed and measured directly on the screen.

Another main area of application is the measurement of complex hidden geometries that cannot be measured tactilely or optically. The component surface can be extracted from the model and returned to CAD systems as an STL file (reverse engineering).