Defect analysis and void inspection using industrial computed tomography scanning

Quantitative defect analysis makes imperfections, inclusions, and cracks visible in 3D

Gas inclusions, shrinkage, bonding defects, or hidden foreign particles jeopardize the service life of critical components in automotive, aerospace, medical technology, and additive manufacturing. Component testing using industrial computed tomography (CT) provides your team with non-destructive damage analysis, including precise volume and location determination of each defect. We deliver the results as a comprehensive 3D volume data set including a color-coded heat map of the findings. These can also be output as an Excel list and/or PDF report. Analyses compliant with the P201 | P202 | P203 standards are also possible. This allows you to make informed approval decisions without destroying components. Once the CT inspection has been completed, we will be happy to explain your data to you via video call.

Your advantages at a glance

- Volume-based pore & void inspection: Critical volume / defect size can be defined as min/max

- Defects at a glance: In the inclusion analysis, foreign particles and impurities are automatically classified and color-coded.

- Possibility of defect analysis based on P201 / VW 50097, P202 / VW 50093 and in accordance with P203

- Compared to micrographs, ultrasound, and 2D X-ray: Maximum informative value via CT inspection due to millions of data points.

- Accredited testing and testing laboratory: DIN EN 15708-3 and DIN EN ISO/IEC 17025:2018

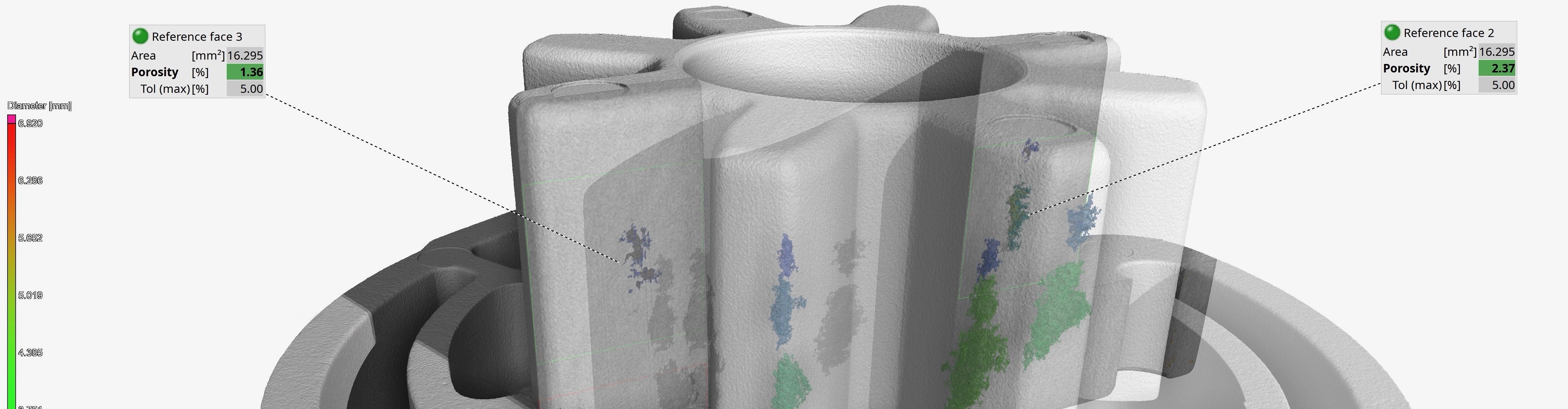

Damage analysis: Pore testing in die-cast aluminum

During the production of die-cast valve blocks, cavities or pores can form, which can lead to leakage problems or component failure. A CT-supported porosity analysis provides a completely reconstructed 3D volume in which even deep cavities are highlighted in color. Clusters at critical points — such as areas subject to high mechanical or thermal stress — can thus be clearly identified without destructive testing of the cast component. This information can be used to specifically adjust casting parameters or to make statements about tightness and functionality. As an alternative to ultrasound or micrographs, industrial ct scanning provides 3D data, whereas component micrographs can only be produced destructively, ultrasound is not applicable to complex geometries, and 2D X-rays only show projections. This means that industrial computed tomography scanning provides you with the most meaningful information.

Examples of suitable materials

We use industrial computed tomography scnanning to non-destructively measure components and various materials from the automotive, medical technology, and aerospace industries. Examples:

- Aluminum, magnesium, and zinc die casting

- Titanium, Inconel Additive manufacturing components

- Steel and sintered metal castings

- Polymer and fiber composite materials (CFRP, GFRP)

- Ceramics and glass bodies

- Elastomers / rubber damping elements

The process – safe and fast analysis

| 1..Setting objectivesg | In a non-binding initial consultation, you can ask our experts about the test criteria (material, scan resolution, etc.) and define the areas you want to examine (partial scan/point of interest or full scan). |

| 2. Fast quote | You will usually receive a complete quote for your industrial CT inspection at a fixed price on the same working day. |

| 3. Shipping | Send or deliver the component to be inspected to TPW CTinspect in Neuss, Germany. A non-disclosure agreement (NDA) is a matter of course for us. |

| 4. CT scan | The CT scan is carried out in our accredited testing laboratory within a few working days. Your individual target date is agreed in advance and confirmed again in the quote. |

| 5. Analysis & evaluation | The measurement data compiled for you will be made available in our secure download area. (Example: images with different section planes and/or test report including false color representation, 3D volume model, or statistics. |

| 6. Our additional service | We are happy to discuss and analyze your data with you in a video meeting. This allows you to benefit from our decades of experience in the field of industrial CT scanning free of charge. |

Scope of delivery of the CT scan

- 3D volume data set (.vgl)

- Quantitative analysis (CSV/Excel table with pore size, volume, coordinates)

- Color-coded defect heat map (viewer file & JPG sections)

- Detailed PDF test report including statistical summary (histograms)

- Password-protected access to your data and server location in Germany

Our CT engineers are available for an online review

Excerpt from our CT scan portfolio

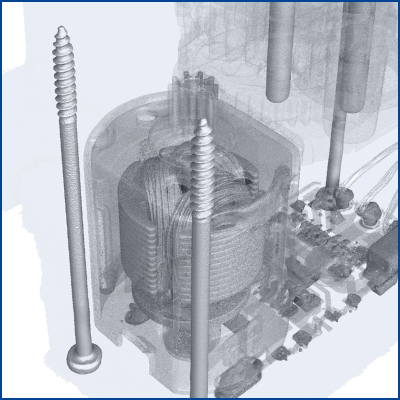

Assembly analysis and assembly inspection

Analyze all components of an assembly without disassembly using industrial CT scanning.

LEARN MORE

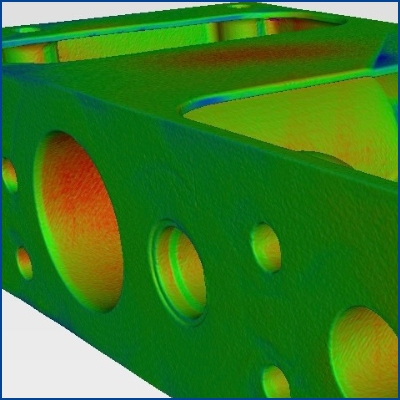

Nominal/actual comparison

Nominal/actual analysis provides you with a color-coded CT scan that immediately highlights any deviations.

LEARN MORE

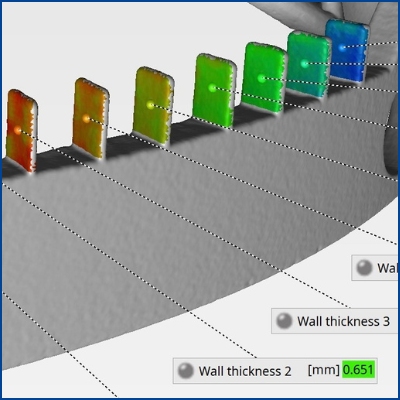

Wall thickness analysis and wall thickness measurement

Compare or analyze your component geometry by measuring wall thicknesses without contact.

LEARN MORE