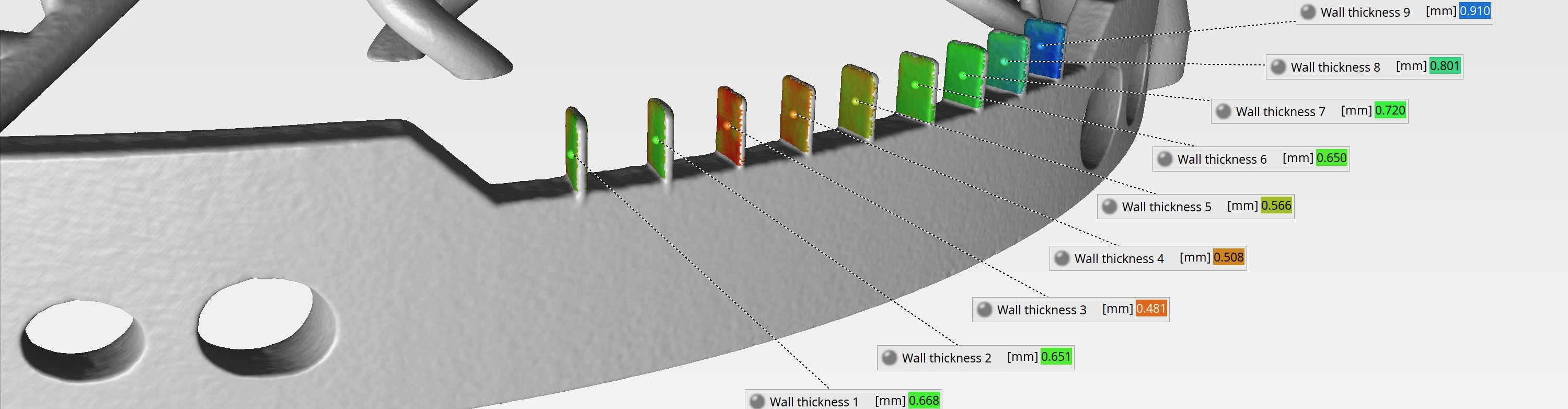

Wall thickness measurement using industrial computed tomography

Measure wall thickness and immediately check critical weak areas

Thin-walled die-cast parts, additively manufactured cooling channels or bonded automotive components must function flawlessly despite material optimisation. Wall thickness measurement using ultrasonic or 2D X-ray methods quickly reaches its physical limits with complex components – overlaps and dependency on the viewing direction prevent accurate results. Industrial CT generates a detailed volume model and enables automated wall thickness measurement at every point of the component.

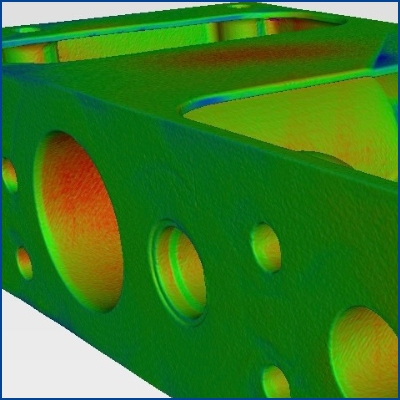

Colour-coded heat maps, i.e. colouring of the component according to wall thickness, immediately show where walls are too thin, too thick or uneven. TPW CTinspect thus helps suppliers in the automotive and aerospace industries, as well as AM manufacturers, with damage analysis and the potential prevention of functional failures. You will receive the results of the CT scan as a report in PDF format, and our experts are also available for a free, personal analysis of your data via video call.

Core functions of CT-based wall thickness measurement

- Dimensional accuracy at a glance: 3D heat map (false colour representation) of the wall thickness of the entire component – critical areas immediately catch the eye

- Automatic min/max search: algorithms find the thinnest and thickest wall thicknesses

- Sub-voxel accuracy: High measurement accuracy thanks to spherical search method, even with complex geometries

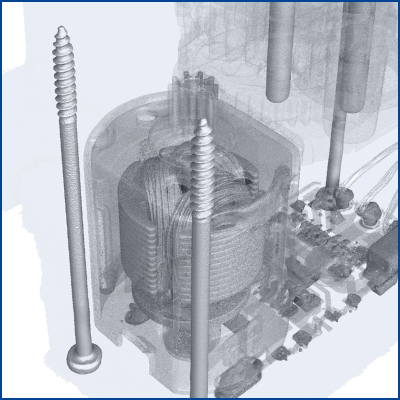

- CT testing as an alternative to X-ray and ultrasound: CT also measures internal geometries and undercuts; 2D X-ray is dependent on the viewing direction, ultrasound is only suitable for easily accessible areas with flat surfaces

Wall thickness measurement of additively manufactured metal components

Delicate metal components manufactured additively using powder bed processes often feature complex free-form surfaces and internal structures. A CT-based wall thickness analysis generates a colour-coded 3D model that provides a holistic view of even hard-to-reach areas. Deviations from the target thickness are immediately visualised, allowing design and process parameters – such as laser parameters, printing speed or support geometry – to be optimised.

Materials that can be tested for wall thickness using CT

Industrial computed tomography enables non-destructive component measurement of many materials used in the automotive, medtech and aerospace industries. Examples:

- Aluminium, magnesium and zinc die-castings

- Titanium and Inconel AM components

- Steel and sintered metal castings

- Reinforced thermoplastics (CF/GF) and thermosets

- Ceramic substrates and glass bodies

- Elastomers, seals

How we inspect for you

| 1. Joint definition of objectives | In a non-binding initial consultation, our experts will advise you on the test criteria (material, scan resolution, etc.) and determine the areas to be analysed (partial scan/point of interest or full scan). |

| 2. Quick quote | Typically, you will receive a comprehensive fixed-price quote on the same working day. |

| 3. Logistics | You can send or deliver your component to TPW CTinspect in Neuss, Germany. Non-disclosure agreements (NDAs) are a matter of course for us. |

| 4. CT Inspection | We conduct the certified CT scan within a few working days in our accredited testing laboratory. We schedule your individual timetable in advance and confirm it in the quotation. |

| 5. Analysis & Reporting | You will receive the measurement data processed for you in our secure download area (e.g. 3D volume model, sectional images and/or test report including false colour representation or statistics). |

| 6. Our service | Our service → Upon request, we are happy to analyse your data jointly in a video meeting. Benefit from our decades of experience in CT services – free of charge! |

Deliverables & analysis data provided

- Colour-coded 3D heat map (viewer file *.vgl)

- Excel/CSV table with measurement data such as wall thickness (min/max) & position

- PDF test report including histogram & min/max overview

- STL mesh for CAD comparisons or CAE simulation

- Data security: Server location in Germany and password-protected download of your CT data

In addition, we are also happy to assist you in interpreting the data, e.g. in an online meeting.

Further CT inspection methods

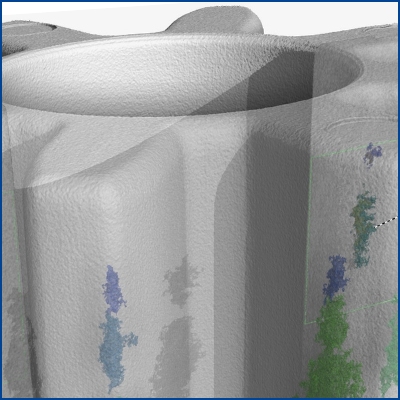

Defect inspection and pore analysis

The CT analysis reliably shows gas inclusions, shrinkage, bonding defects or hidden impurities.

LEARN MORE

Assembly inspection & component analysis

The interior view of all joints or assembly errors can be detected without any disassembly.

LEARN MORE

Target/actual comparison

A colour-coded target/actual analysis using industrial computed tomography is suitable, for example, for measuring the tolerances of complex components.

LEARN MORE