Reverse engineering with industrial computed tomography scanning

Complete 3D digitization of internal and external geometry – ready for CAD, simulation, and additive manufacturing.

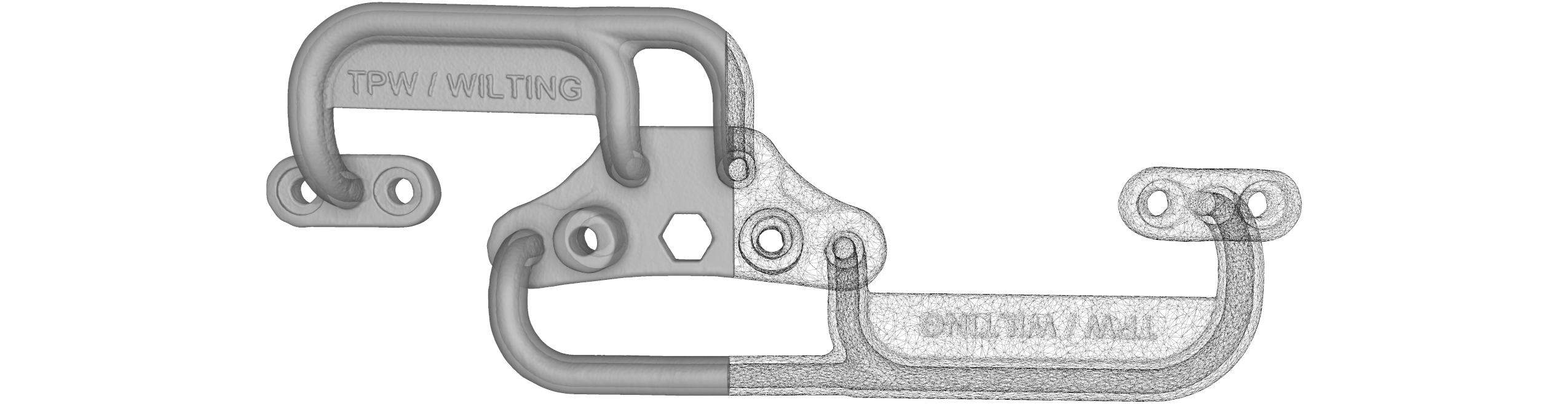

Industrial computed tomography scanning at TPW CTinspect generates a detailed STL data set, e.g. for your surface reconstruction. Unlike optical 3D scanners, CT scanners also captures hidden internal structures, undercuts, and lattice structures, thus offering a highly realistic 3D component reconstruction. Designers, quality and test engineers thus gain a usable digital twin for reverse engineering, FEA simulation, or spare parts production — without disassembly or destructive cross-sectioning. Once the CT scanning is complete, we will be happy to conduct a free, individual evaluation of your CT analysis with you via video conference.

Core functions reverse engineering using industrial CT scanning

- High-resolution STL data: Can be used directly in CAM, CAD, or FEA

- Validation/falsification of simulation data: Comparison of actual data with FEA analysis

- Creation of digital twins: Geometry data for further analysis or archiving

- DIN EN ISO/IEC 17025:2018 accreditation for testing laboratories includes CT standard DIN EN 15708-3:2019

- Secure data transfer: Server location in Germany, password-protected customer area

Digital twin for spare parts manufacturing

Classic car assemblies that are neither available as spare parts nor documented in technical drawings can be reproduced using reverse engineering. TPW CTinspect uses CT scanning to capture the entire component volume – including winding channels, hidden webs, and undercuts that are not accessible from the outside. This data is first used to create an STL polygon mesh, which you can then convert into a parametric CAD model for surface reconstruction.

Depending on their complexity, spare parts can then be manufactured using additive manufacturing or CNC machine tools.

Selection of materials that can be fully digitized using CT scanning

Industrial CT scanning enables the examination of a wide range of different materials. Here is a selection of some of the materials:

- Light metals, especially thin-walled components manufactured using additive manufacturing from:

- Aluminum alloy

- Magnesium alloy

- Titanium

- Glass fiber & carbon fiber reinforced plastics

- Technical ceramics & glass

- Elastomers, sealing layers, and coatings

This is the CT scan process

| 1. Joint definition of objectives | Our non-binding initial consultation gives you the opportunity to ask our experts directly about the test criteria (material, scan resolution, etc.) and to define the areas to be analyzed (partial scan/point of interest or full scan). |

| 2. Quick quote | You will usually receive a complete quote at a fixed price on the same working day. |

| 3. Logistics | Send or deliver your component to TPW CTinspect in Neuss, Germany. Confidentiality agreements (NDAs) are a matter of course for us. |

| 4. CT inspection | We carry out the CT inspection within a few business days in our accredited testing laboratory. We agree on your individual schedule in advance and confirm it again in the quote. |

| 5. Analysis & reporting | Your data will be made available to you in our secure download area. (Examples: cross-sectional images and/or test report including false color representation, 3D volume model, or statistics). |

| 6. Our service | We are happy to discuss your data with you in a video meeting and analyze it together. Benefit from our decades of experience in CT services—at no additional cost! |

Your CT results at a glance:

- CT volume data set (file format: *.vgl)

- STL export data for further processing/surface reconstruction

- Password-protected download area for your CT analysis data & server location in Germa

If you have any questions about evaluating the data, we will be happy to assist you via online meeting.

Further CT scanning service portfolio

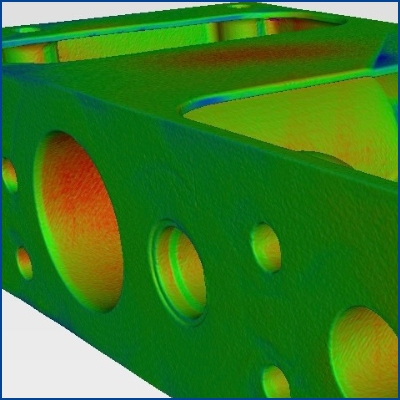

Geometry comparison & nominal/actual analysis

Color-coded nominal/actual analysis using industrial computed tomography, e.g., for measuring the tolerances of internal structures.

LEARN MORE

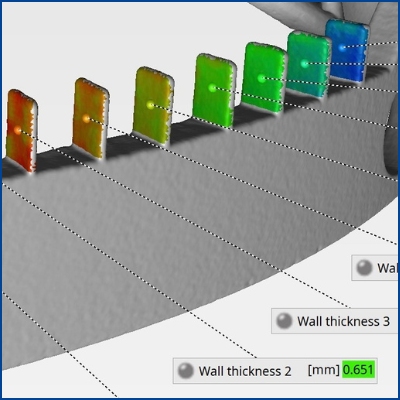

Wall thickness measurement / wall thickness analysis

The 3D heat map (false color image) resulting from the CT scan illustrates the wall thickness of the entire component.

LEARN MORE

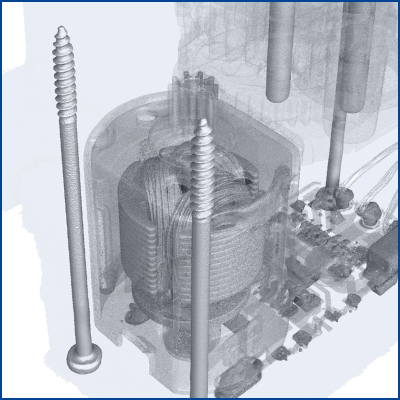

Assembly verification and component analysis

Analyze functionally critical assemblies non-destructively using CT scanning and without disassembly.

LEARN MORE