Nominal/actual analysis & geometry comparison with industrial CT scanning

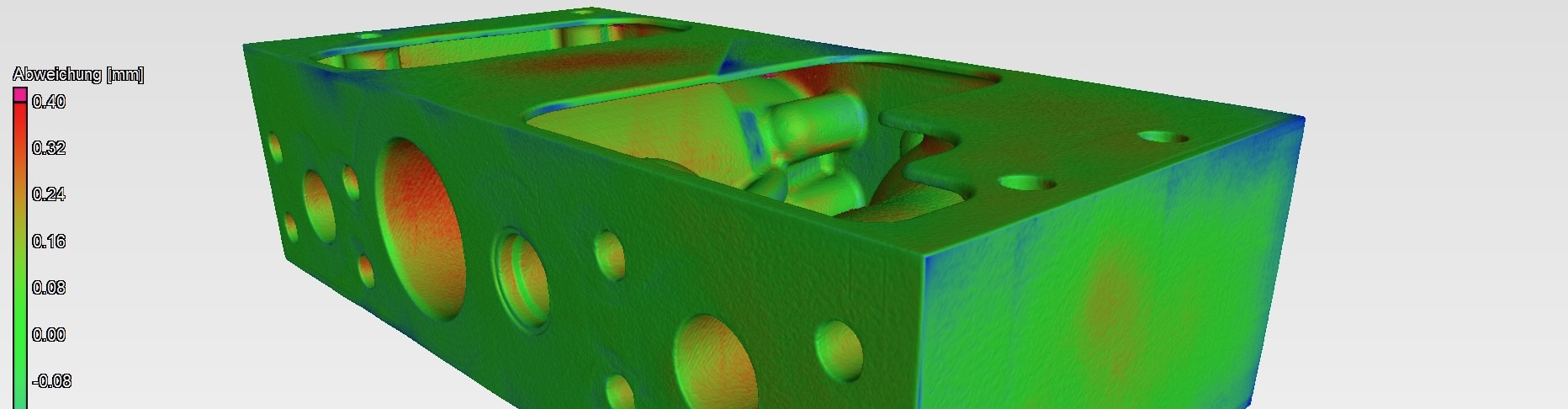

False color representation shows deviations on inner and outer surfaces

The precise fit of internal structures, e.g., an additively manufactured metal component or cast component, can easily go undetected during tactile or optical contour measurement. Industrial computed tomography (CT) provides a complete volume model of your component — including internal geometries that are not accessible from the outside — and automatically compares it with your CAD data set. The result: a color-coded target/actual analysis in the µm range, supported by histograms and a frequency distribution of all deviations. Development and QA teams in the automotive, aerospace, and medical technology industries can thus identify critical tolerance violations early on, reduce rework loops, and bring products to series production faster. After we have performed your CT scan, we will assist you in interpreting the data, e.g., via video call.

Core functions of CT-supported nominal actual analysis

- False color representation: Deviations in the µm range are immediately apparent – no time-consuming single-point analysis

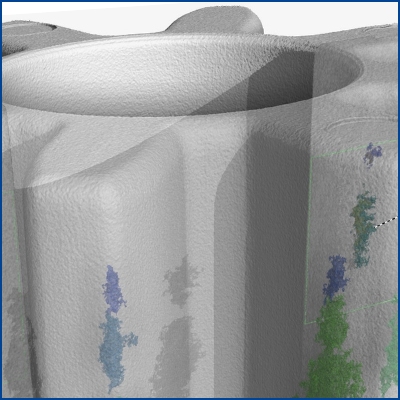

- Nominal/actual component interior: CT scanning captures internal channels and lattice structures – not possible with optical 3D scanning or coordinate measuring technology (CMM)

- Statistical frequency distribution: e.g., "95% of the surface < 0.25 mm deviation"

Application example: Nominal-actual analysis for additively manufactured cooling channels

In the additive manufacturing of complex cooling channels in mechanical engineering, a CT-supported nominal-actual analysis ensures that the internal flow channels follow the CAD contour exactly. The false color image projected onto the 3D volume model makes over- or undersized areas immediately recognizable. Based on the heat map, support structures and laser parameters for the sintering process can be specifically adjusted so that the subsequent series components reliably achieve the planned flow rate and thermal performance.

Materials that can be checked for geometric deviations using CT scanning

Industrial CT scanning can be used to analyze various materials. A selection of some materials can be found here:

- Aluminum, magnesium, titanium

- AM components

- Sintered metal or cast parts

- Glass fiber & carbon fiber composite materials

- Ceramics & glass

- Elastomers, sealing materials

This is how your CT scan works

| 1. Joint definition of objectives | Our non-binding initial consultation gives you the opportunity to ask our experts directly about the test criteria (material, scan resolution, etc.) and to define the areas to be analyzed (partial scan/point of interest or full scan). |

| 2. Quick quote | You will usually receive a complete quote at a fixed price on the same working day. |

| 3. Logistics | Send or deliver your component to TPW CTinspect in Neuss, Germany. Confidentiality agreements (NDAs) are a matter of course for us. |

| 4. CT inspection | We carry out the CT scan within a few working days in our accredited testing laboratory. We agree on your individual schedule in advance and confirm it again in the quote. |

| 5. Analysis & reporting | The measured data prepared for you will be made available in our secure download area. (Examples: cross-sectional images and/or test report including false color representation, 3D volume model, or statistics). |

| 6. Our service | We are pleased to offer a video meeting to discuss your data and perform a joint analysis. Our company has many years of experience in CT services. You can benefit from this experience at no additional cost. |

What you receive after the CT scan

- False color comparison "3D heat map" (file format: *.vgl)

- Test report (PDF) with threshold value histogram & min/max key figures

- Optional: Excel/CSV statistics of all deviations; STL mesh for CAD comparison or CAE simulation

- Secure data transfer: Server in Germany and 3D data with password protection

If you have any questions about the evaluation afterwards, our CT specialists are available for a web meeting - free of charge.

Further CT scanning methods from TPW CTinspect

Pore analysis and shrinkage inspection

CT scanning is a reliable tool for identifying gas inclusions, shrinkage, bonding defects, or hidden foreign particles.

LEARN MORE

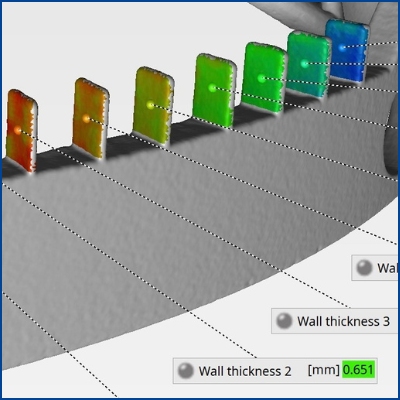

Wall thickness analysis and wall thickness measurement

3D heat maps visually show the deviations in wall thickness within a component.

LEARN MORE

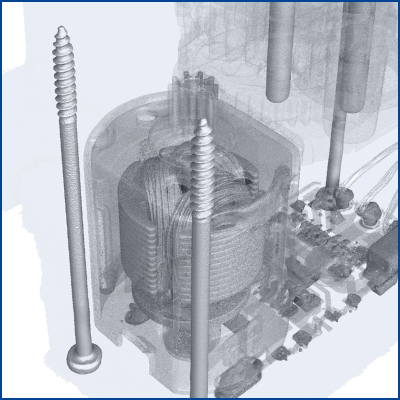

Assembly verification and component analysis

Assembly verification using industrial computed tomography scanning enables the rapid detection of missing components or incorrectly assembled components.

LEARN MORE