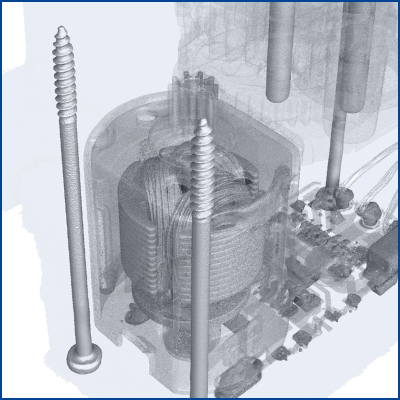

Fiber orientation analysis with industrial computed tomography scanning

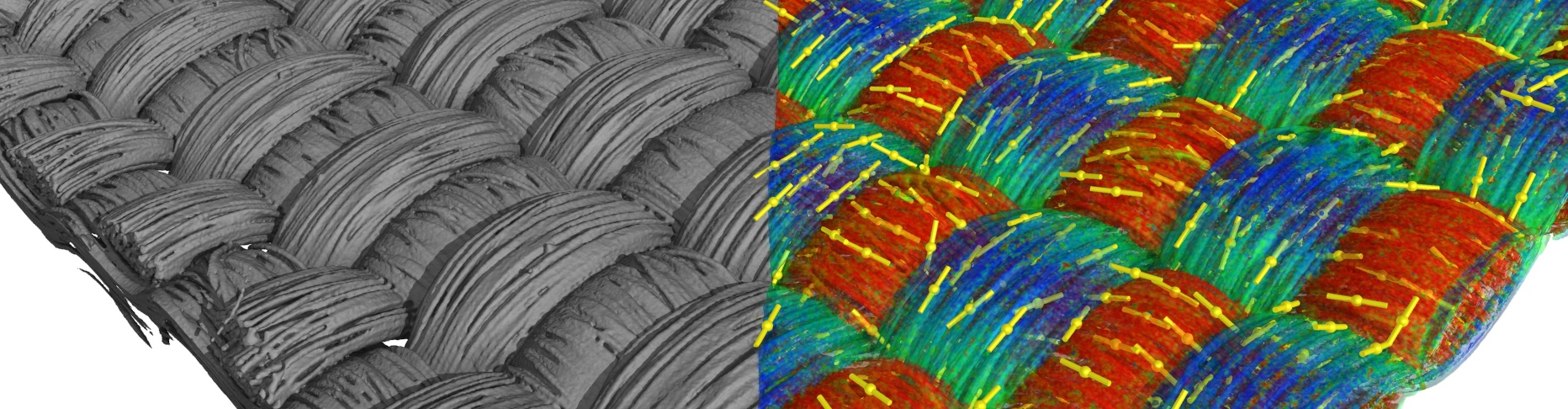

3D visualization of fiber orientation reveals weak points in CFRP and GFRP structures

In high-performance composites, the exact fiber orientation determines stiffness, crash behavior, and service life. Optical methods only capture the surface; micrographs destroy the component. Industrial CT scannnig at TPW CTinspect visualizes the entire fiber orientation — from the top layer to the core — and provides reliable data for layup optimization, process monitoring, and damage prevention. After the CT scan, we will be happy to discuss your data in detail via video call to help you interpret the results. Free of charge and as an additional service for you.

Core functions of CT-based fiber inspection

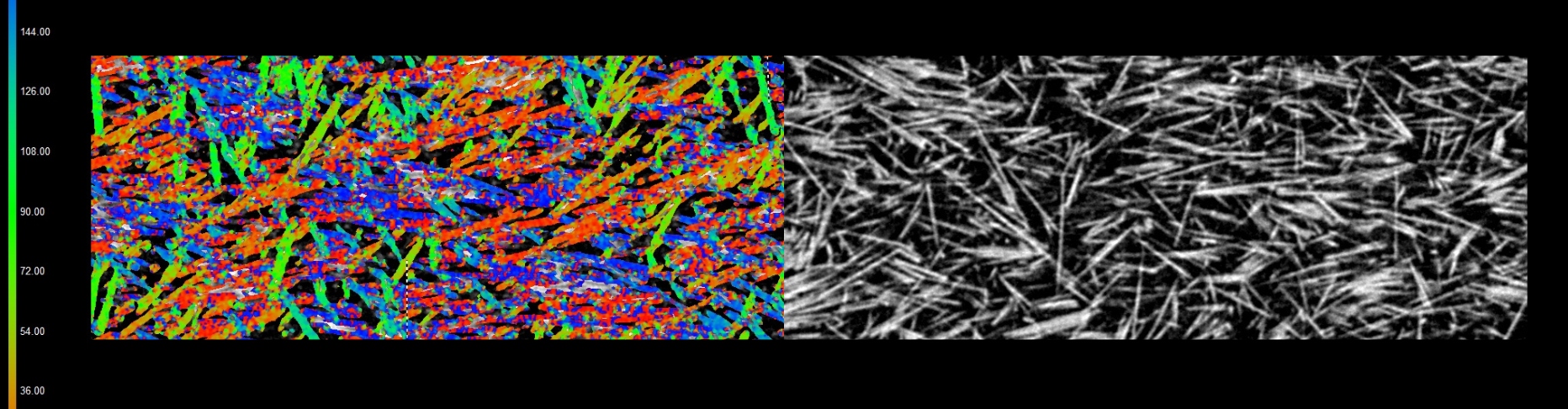

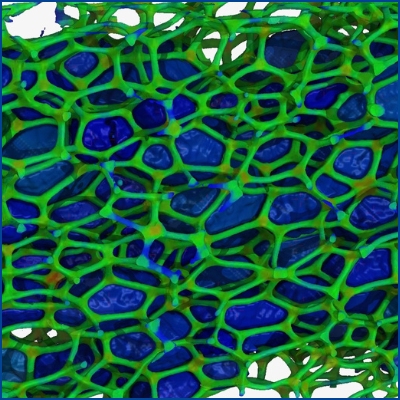

- Color heat map of fiber angles: Orientation and fiber angles are displayed in color

- Automatic statistics: Measurement of the relative volume fraction

- Comparison with ultrasound & cross-section: CT provides non-destructive volume data without destroying the component

- Large number of section planes and angles: Up to 1000 sections per millimeter possible

- Accredited testing: DIN EN ISO/IEC 17025:2018 and DIN EN 15708-3

Application example: Compare fiber orientation in GRP components with FEA simulation

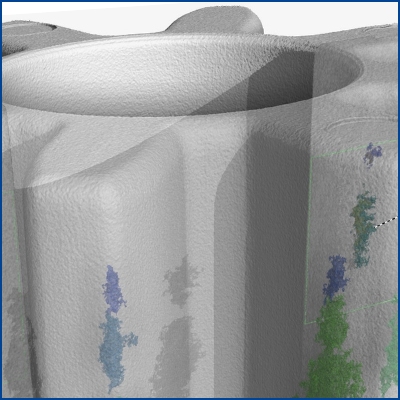

Many of our customers simulate fiber orientation in the manufacturing process using finite element analysis. To ensure that the manufacturing reality and simulation really match, components can be measured using industrial computed tomography after the injection molding process. The resulting 3D heat map shows the actual fiber orientation layer by layer. The orientation data can then be exported as a CSV file. In contrast to destructive micrographs (10-20 sections per 3 mm), industrial CT scanning allows for approximately 3000 section planes and section angles, which significantly increases the qualitative significance of the measurement, so that even very local changes in fiber orientation can be displayed.

Materials that can be tested using CT scanning:

CT testing can be used to analyze various composite materials. Here are a few selected material combinations.

- CFRP laminate (carbon fiber fabric)

- GRP assemblies for automotive and wind power

- Hybrid layups (CFRP + metal insert)

- Textile materials

How your CT scan works

| 1. Joint definition of objectives | In a non-binding initial consultation, our experts will advise you on the test criteria (material, scan resolution, etc.) and determine the areas to be analyzed (partial scan/point of interest or full scan). |

| 2. Quick quote | You will usually receive a comprehensive quote at a fixed price on the same working day. |

| 3. Logistics | You send or deliver your component to TPW CTinspect in Neuss, Germany. Non-disclosure agreements (NDAs) are a matter of course for us. |

| 4. CT inspection | We carry out the certified CT scan within a few working days in our accredited testing laboratory. We agree on your individual due date in advance and confirm it in the quote. |

| 5. Analysis & reporting | You will receive the measurement data prepared for you in our secure download area (e.g., 3D volume model, cross-sectional images, and/or test report including false color representation or statistics). |

| 6. Our service | Upon request, we will discuss your data in a video meeting and analyze it together. Benefit from our decades of experience in CT services — free of charge! |

Your results at a glance

- 3D volume data set (.vgl) with segmented fiber path

- Color heat map of fiber angles as viewer file

- Orientation distribution histogram (.csv / .xlsx)

- Secure data transfer and password-protected data (server in Germany)

If you have any questions about the data, we are happy to assist you via online meeting (e.g., MS Teams).

Selection of additional CT scanning services

Structural analysis & particle analysis

TPW CTinspect's industrial CT scanning enables non-destructive measurement of the entire volume of foams or bulk materials.

LEARN MORE

Cavity testing & pore testing

Non-destructive pore analysis and crack testing are performed using CT testing, including defect analysis.

LEARN MORE

Assembly verification and component analysis

Internal joints or assembly errors can be detected using CT scanning without dismantling.

LEARN MORE