Industrial computed tomography scanning for 3D measurement of components

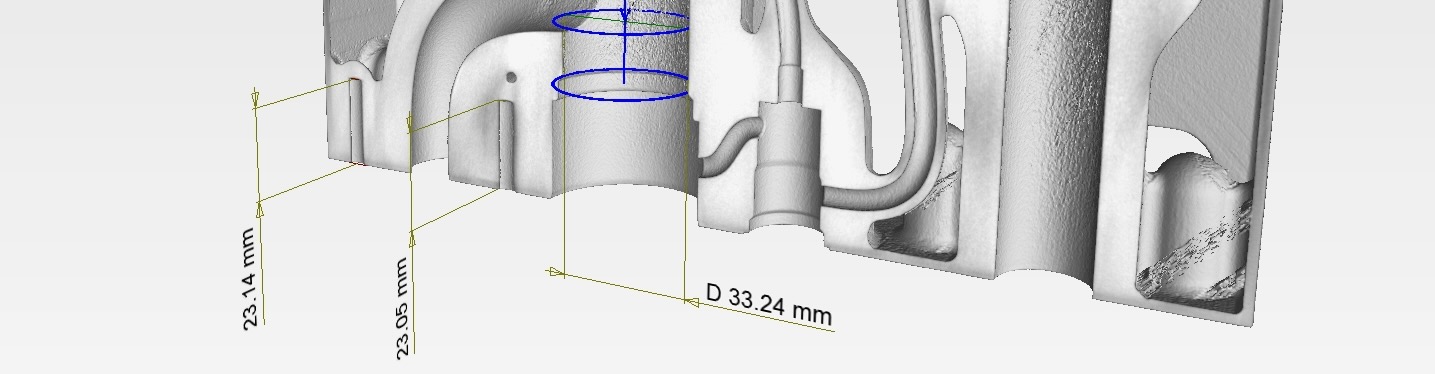

3D X-ray inspection for precise wall thickness measurement, volume measurement, and contour measurements

Industrial computed tomography (CT) scanning combines the strengths of classic coordinate measurement technology and optical measurement systems – without their weaknesses. Instead of point or surface data, you receive a complete volume model of your component. Internal channels, undercuts, or lattice structures from additive manufacturing are captured contactless and without destruction.

Your advantages with industrial computed tomography scanning

Industrial CT scanning provides reliable 3D measurement for additively manufactured metal components. Volume measurement captures all internal and external structures. This data can be used to check dimensional accuracy and perform tolerance analysis in the micrometer range. In addition, defects in additive manufacturing, such as support structures or powder residues remaining in the component, become visible. As a CT service, the process is part of industrial metrology.

- UComprehensive 3D reconstruction: volume measurement & dimensional accuracy testing on internal & external features

- Precise measurement technology even for transparent, reflective materials, components, or surfaces

- Complete component measurement of microcomponents and smallest structures where tactile measurements are impossible

- 3D measurement of flexible, soft, or deformable materials (rubber seals, foam)

- Through local partners at the TPW CTinspect company location in Neuss, Germany, also in combination with tactile and optical 3D measurement technology

Material testing using industrial measurement technology

Industrial computed tomography scanning enables non-destructive component measurement of many materials from the automotive, medical technology, and aerospace sectors:

- Metallic materials:

- Light metals and metal alloys

- Magnesium alloys

- Metallic sintered materials

- Aluminum, titanium, and many more.

- Transparent materials:

- Glass

- Plastics such as PMMA or PC

- Other materials:

- High-performance ceramics and much more.

How we perform your CT measurement

| 1..Setting objectives | In a non-binding initial consultation, you can ask our experts about the test criteria (material, scan resolution, etc.) and define the areas you want to examine (partial scan/point of interest or full scan). |

| 2. Quick quote | You will usually receive a complete quote at a fixed price on the same working day. |

| 3. Shipping | Send or deliver the component to be inspected to TPW CTinspect in Neuss, Germany. A non-disclosure agreement (NDA) is a matter of course for us. |

| 4. CT Scan | The CT scan is carried out in our accredited testing laboratory within a few working days. Your individual schedule will be agreed in advance and confirmed again in the quote. |

| 5. Analysis & Evaluation | The measurement data compiled for you will be made available in our secure download area. (Example: images with different section planes and/or test report including false color representation, 3D volume model, or statistics. |

| 6. Our additional service | We are happy to discuss and analyze your data with you in a video meeting. This allows you to benefit from our decades of experience in the field of CT services free of charge. |

Delivery item: Complete 3D data set including tolerance analysis

Whether it's a single test or a series of tests, at TPW CTinspect you get exactly what you need for your further analysis:

- UComprehensive test report of your CT inspection

- Processed 3D data set according to your requirements

- Complete STL data from your CT scan

- 3D data set for performing your own measurements

- JPG or PDF data of individual cross-sections

- Secure data transfer via a server in Germany and password-protected access to your 3D data

Further CT scanning services by TPW CTinspect from Neuss, Germany

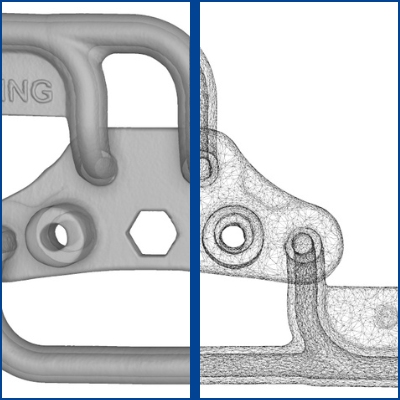

Reverse engineering with industrial computed tomography

Create digital twins – with industrial CT scanning to generate STL data sets, e.g., for your surface reconstruction.

LEARN MORE

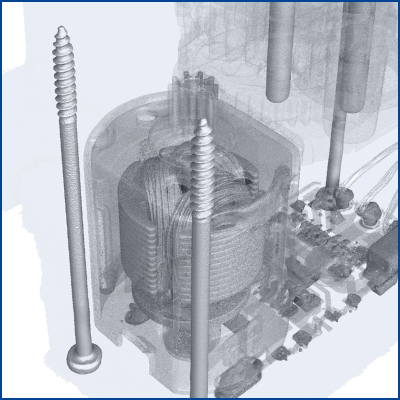

Assembly inspection & component analysis

Analyze functionally critical components without disassembly using 3D X-ray inspection.

LEARN MORE

About TPW CTinpsect

For more than two decades, we have been providing CT inspections to our global customers.

LEARN MORE