CT Testing: Wage measurement using industrial computed tomography

Non-destructive material testing and component measurement as a service – accredited and fast

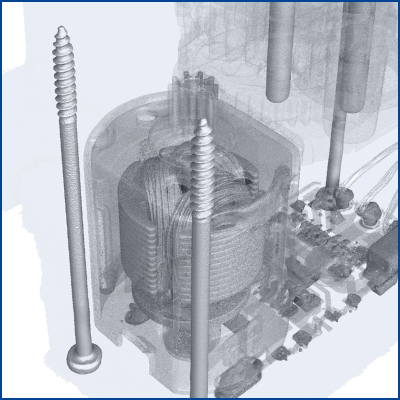

We provide you with 3D X-ray images of your components, including cost-efficient analyses and rapid implementation!

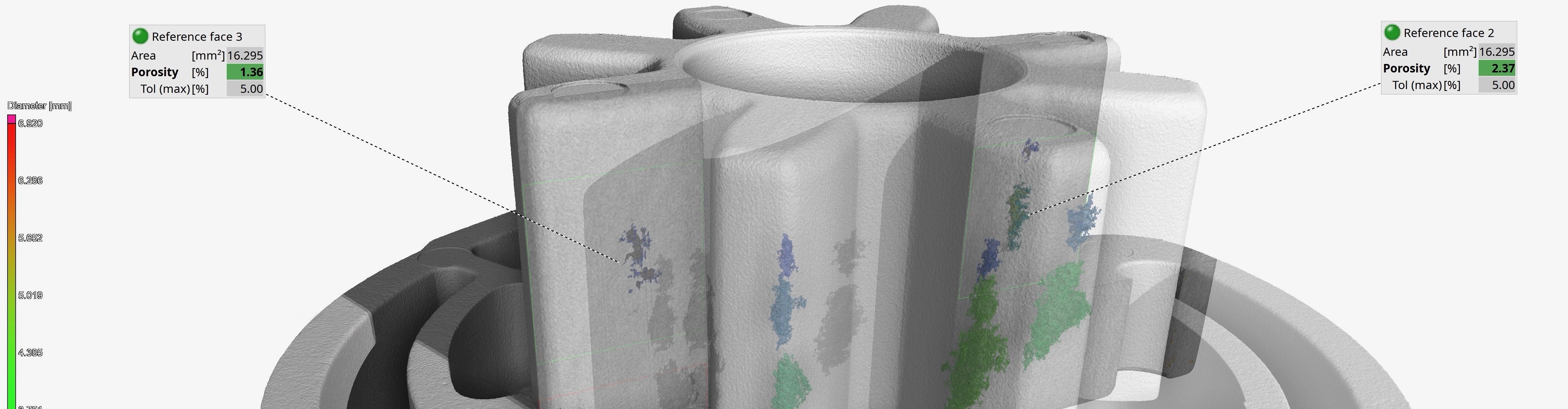

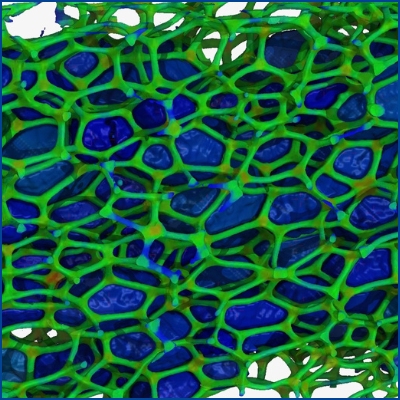

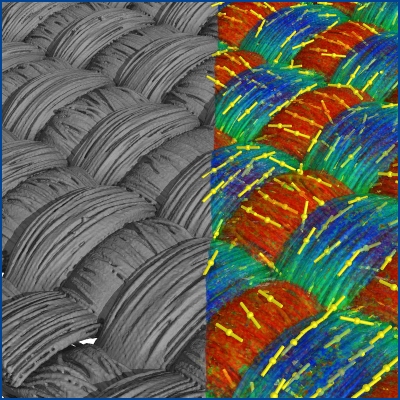

Whether it’s additively manufactured metal components, medical implants, or high-performance automotive parts – with industrial computed tomography services from TPW CTinspect, design engineers and quality inspectors gain quick insight into the internal structure of their components. Precise defect analysis, crack inspection, or porosity inspection form the basis for comprehensive failure analysis.

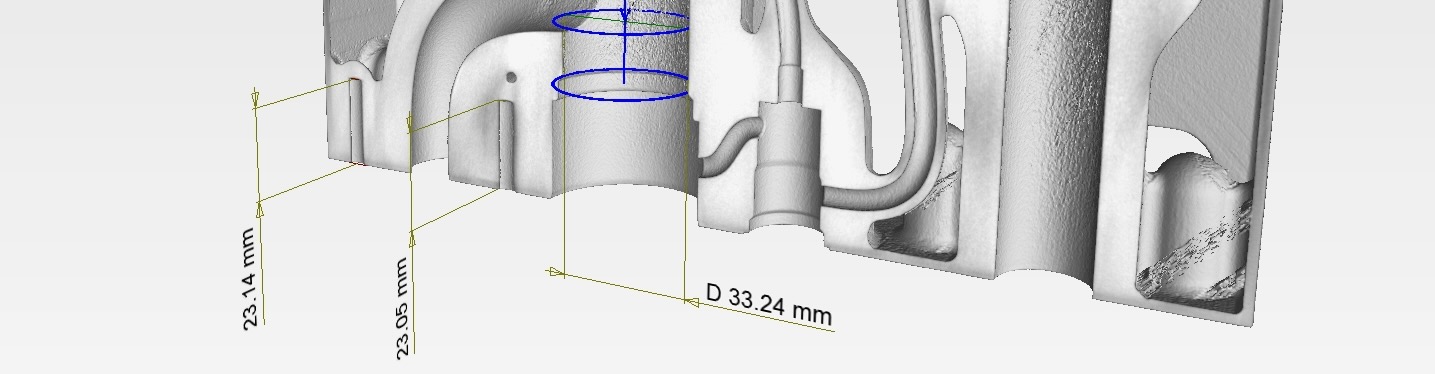

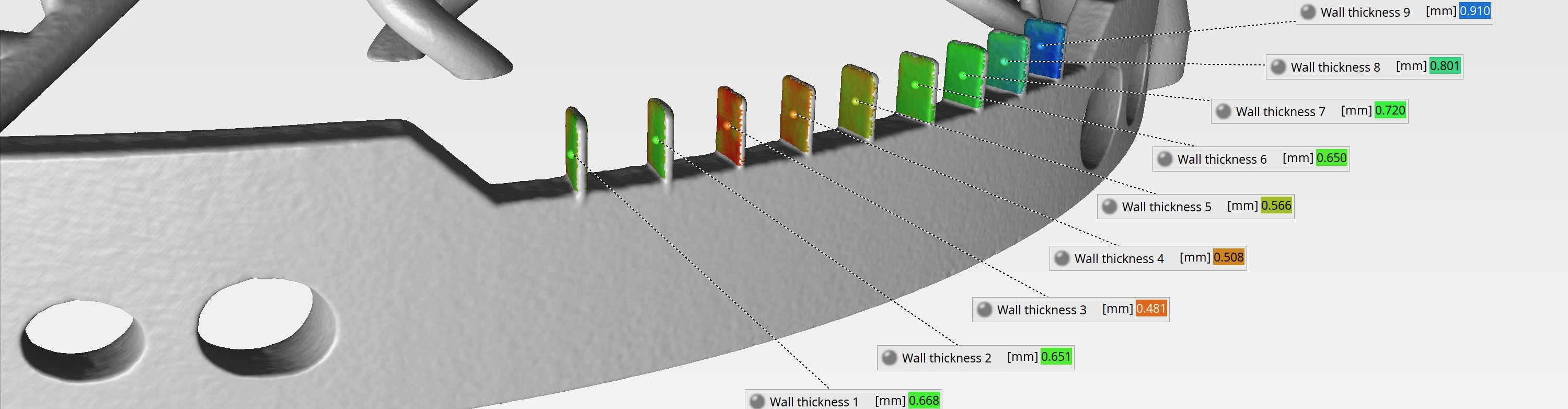

We carry out your component measurements cost-effectively using 3D X-ray inspection, allowing you to check dimensional accuracy, perform tolerance analysis, or measure individual wall thicknesses. With our CT analysis, you can make fact-based decisions just a few days after your components arrive at TPW CTinspect in Neuss. We are happy to offer free and non-binding advice to discuss the most cost-effective and informative CT inspection for your needs.

Computed tomography expertise trusted by industry

- High capacity for single-part and serial inspections: over 10,000 components inspected annually

- Over 45 years of material testing experience with products from additive manufacturing, metal casting, plastics, and composite materials

- Multiple CT systems available for reliability and fast processing

- Accredited testing laboratory (DIN EN ISO/IEC 17025:2018)

- Certified CT inspection (DIN EN 15708-3)

- Free analysis video call with CT engineers

Take a look inside your products!

CT Service by TPW – Added Value for Your Quality Inspection and Metrology:

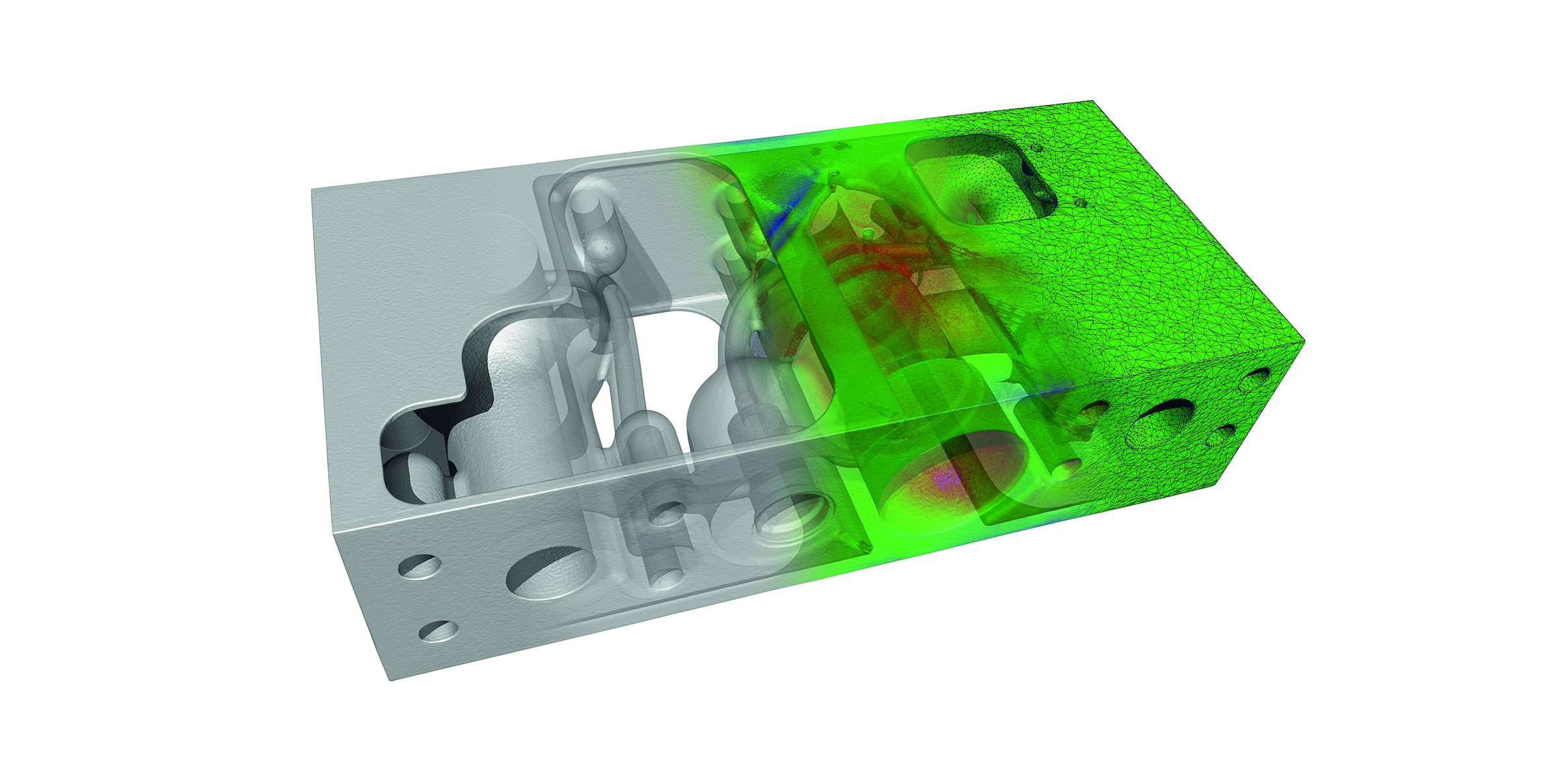

Volume Data Inside & Outside:

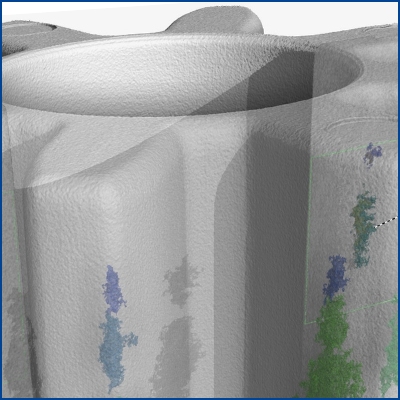

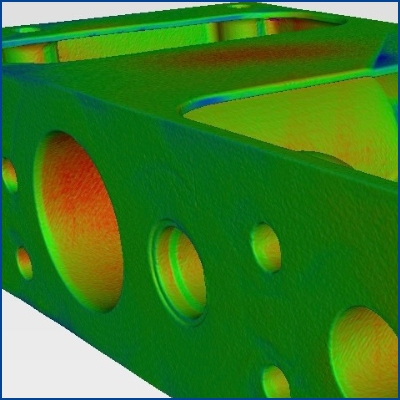

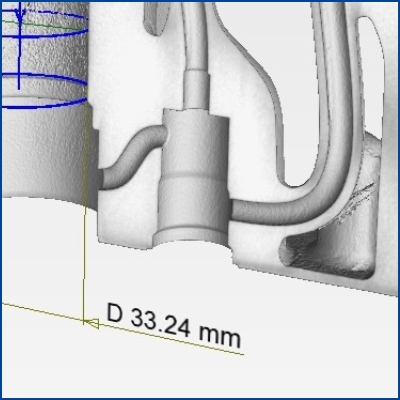

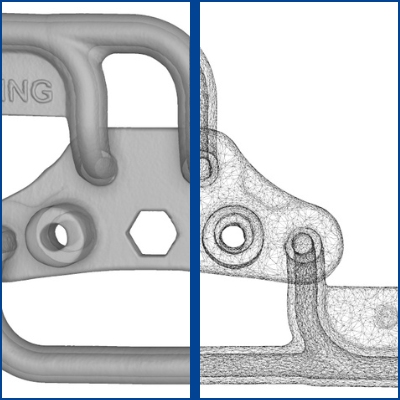

A CT scan captures geometry, pores, inclusions (cracks and voids), as well as undercuts and internal structures (including support structures in AM components).

Fast CT Analysis:

Adapted to your project timeline, we provide comprehensive 3D data and your customized inspection report.

Standard-Compliant Inspection Reports:

We are certified according to DIN EN ISO/IEC 17025:2018 and perform inspections in accordance with DIN EN 15708-3 as well as based on VDG P201, P202, and P203.

Data Export:

You can view the 3D data with a free data viewer (myVGL). Using open file formats (*.stl, *.csv, or *.xlsx), direct transfer to CAD or FEM software is possible.

Enhanced Data Security:

Server located in Germany, password-protected CT analyses, and deletion of your sensitive CT data after project completion.

Broad Testing Portfolio:

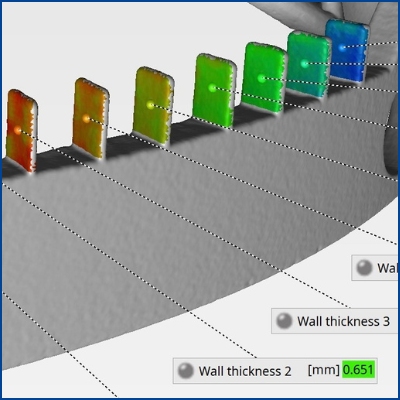

Nominal-Actual Analysis, Assembly Analysis, Porosity Analysis, Component Measurement, Wall Thickness Measurement, Particle Analysis, Fiber Inspection, and Reverse Engineering.

Questions About Industrial Computed Tomography (FAQ)

What are the costs for a CT inspection?

The costs for your CT inspection are calculated on a project-specific basis, as each contract CT inspection meets different requirements. Key factors influencing, for example, the required machine time include component size and weight, desired resolution, and quantity. The scope of analysis also affects the time our specialists need. A simple volume scan is more cost-effective than a full package with, for example, geometry comparison, porosity statistics, or STL export. Depending on the task, there may also be options to automate processes, which can save costs even for small quantities. To provide an accurate quote, we discuss component dimensions, materials, desired resolution, inspection objectives, quantity, and schedule in advance during a consultation – ensuring a reliable price estimate without surprises.

How quickly will I receive results?

Typically, you will receive your CT analysis and 3D volume models within 5–7 working days. If you need results faster, please contact us – we usually find a flexible solution tailored to your project!

How is data security ensured?

Our testing laboratory is accredited according to DIN EN ISO/IEC 17025:2018 – we are happy to sign a non-disclosure agreement (NDA) in advance. Your analysis data is stored on a server in Germany and provided with password protection. After project completion, all data is deleted, ensuring that only our clients retain full control over their data.

Can multiple CT analyses be combined?

Depending on component size and desired resolution, we can combine multiple components per scan to perform dimensional measurements as cost-effectively as possible for you.

What resolution is realistic for 3D measurement?

The achievable resolution depends on component size and various scan parameters, such as the number of projections. For small components, we can achieve a resolution of up to 1 µm; for very large components, the resolution is approximately 0.15 mm. Measurement accuracy for evaluations within 3D coordinate metrology on our metrology CT systems lies in the single-digit µm range.

Do you support OEM specifications?

We perform testing in accordance with P201 / VW50097, P202 / VW50093, and P203 of the VDG or BDG. Measurement accuracy according to VDI 2630 is achievable for components up to 20 kg with a resolution of up to 2 µm. Our testing procedure using industrial computed tomography is certified according to DIN EN 15708-3, and all CT inspections are conducted in our climate-controlled, DAkkS-accredited testing laboratory (DIN EN ISO/IEC 17025:2018, accreditation certificate D-PL-11209-01-00).

Do you have your own specification according to which your components should be evaluated? We will gladly check to what extent we can also meet these requirements.

Office Hours

Our current office hours are:

Monday to Friday, 7:00 a.m. to 5:00 p.m.

Please coordinate any pickups with us in advance.

Job Offers

TPW CTinspect GmbH offers exciting areas of work in constantly new projects for our customers. In addition to applications for our advertised positions, we also welcome unsolicited applications.

LEARN MORE